Last week I had left my brake shoes into Belfast Brake Specialists

The brake drum in the back wheel was pretty well worn and at first I had thought about boring out the remainder and making a new cast iron liner to go inside. Since I've never tackled this job before I wasn't too sure how it would work out, nor did I know just what degree of interference fit I would need between it and the hub for it to be successful, although I could make a good guess, it was still going to be a lot of work.

Previously to get a better brake I had attached shims to the faces of the shoes to try and move them out closer to the drum and give me a shorter pedal travel. There had been so much travel in the pedal it would touch the frame and I didn't want this happening again just to ruin the new paint work.

I decided instead to go about it a different way by relining the shoes with thicker material and skimming them to suit. By measuring the internal diameter of the hub I reckoned a 5mm thick lining to be about right.

I explained all this to Trevor at BBS but he only carried 4.7mm (3/16") or 6mm thick material. Based on the grounds it would be less work I picked the 3/16" material but changed my mind and phoned Trevor the next morning to get him to put the 6mm material on. Even though he had started the job that wasn't a problem, and I picked them up the other day looking like new again. It's always good when you can get excellent service like this from someone local.

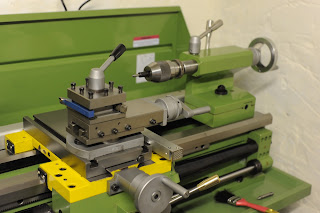

The next day I made a simple mandrel to hold the brake plate, mounted the shoes and tied them together with a piece of wire and a tie wrap to pull them tight against the cam then proceeded to turn them down to size.

The material turned down very nicely to leave a good surface. The internal diameter of the hub is 141mm and I made these shoes 140.8mm

I wasn't sure if this was going to be enough clearance but when I assembled everything the wheel rotates freely without even the faintest sound of the shoes rubbing. So I don't think I could make them any better other than cut grooves across the shoes to displace water, but then I don't plan to be competing on the bike again so I'll leave them as they are.